Engineered Lifting Equipment for Servers

Alum-a-Lift provides computer, server and rack-mount lifts for every major computer manufacturer. Our server rack lifts can also be found in data centers throughout the world.

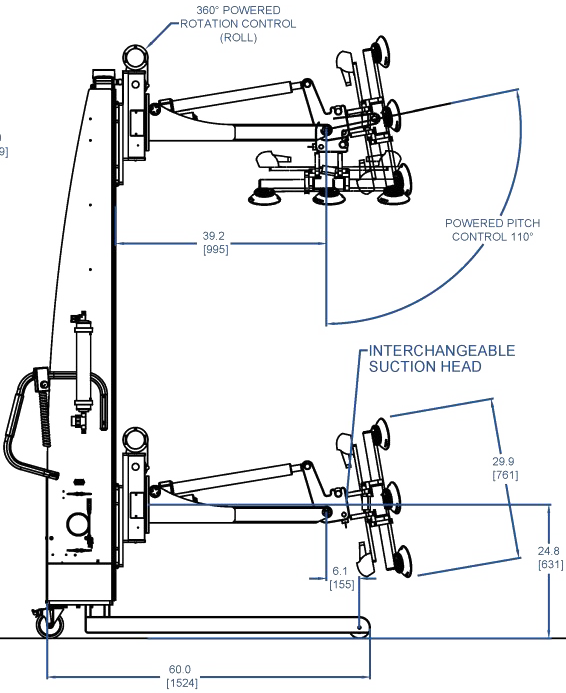

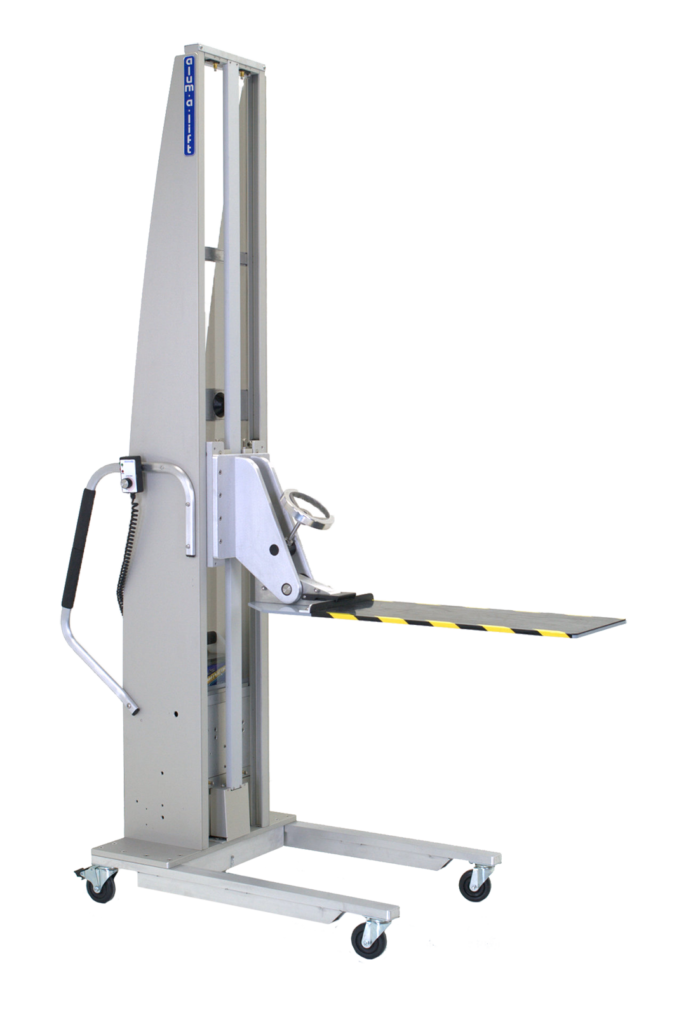

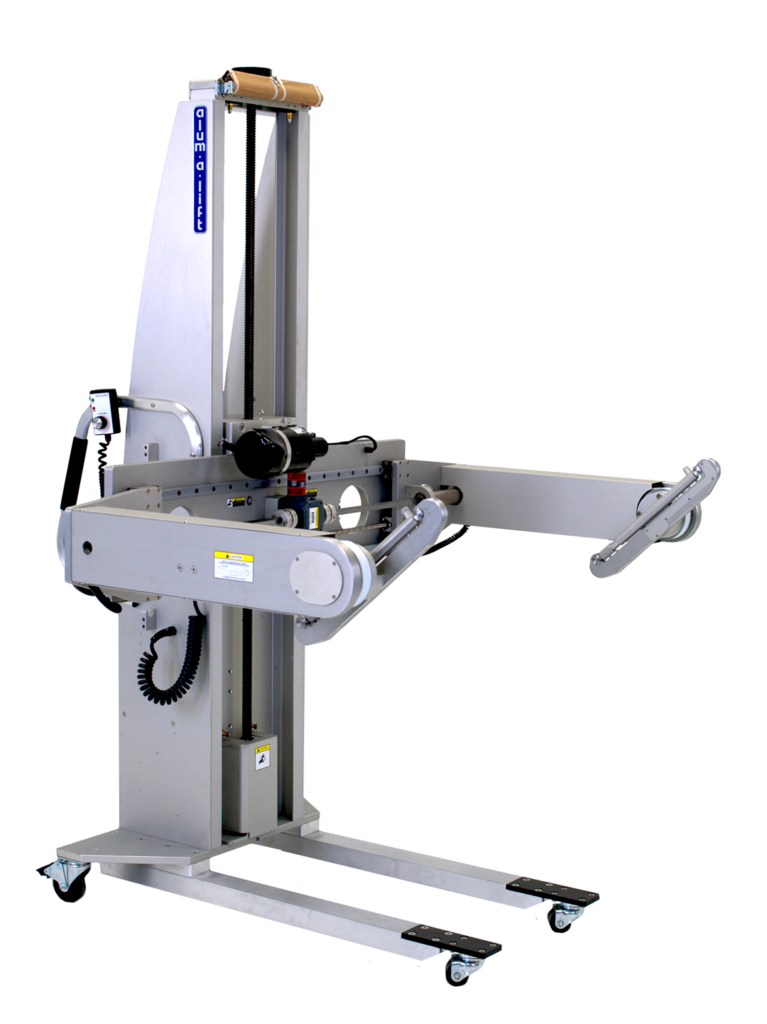

The standard chassis offers proven lifting power and allows for heavier and dynamic side loads. Our end-effectors provide precise manipulation designed specifically for the object you need to handle.

Our tailored lifts are designed to your specifications. We can address electrostatic discharge (ESD) concerns, create lifts that meet cleanroom compliance standards, and build counterbalanced lifts if there are clearance concerns.

Lifts Engineered and Designed

for Seamless Integration

All Alum-a-Lifts are optimized for your equipment, environment, and process.

Easy to Implement

Our engineers minimize system weight and address narrow aisles, overhead obstacles, grated flooring, and other challenges.

Inherently Clean Designs

Keep your workplace clean with our corrosion-resistant chassis and all-electric drive train.

Low Maintenance

With an optional quick-exchange battery system and an average maintenance downtime of only two hours per year, you won’t lose valuable time waiting on your equipment.

Rigorous Testing

To ensure your lift can handle the demanding conditions of the electronics industry, every handling system undergoes rigorous factory testing that simulates actual use as well as extensive QC inspections

Due to their flexibility, Alum-a-Lifts are used throughout the server industry, including computer manufacturing and data center maintenance.

Server Manufacturing

Our lifts allow for safe, repeatable loading of high value components throughout the computer manufacturing process.

Data Centers

Our lifts can be configured with low-friction plastic platforms that allows rail-mounted components to be removed and replaced with ease.

Recent Server Handling Lifts

Alum-a-Lifts are tailored to your specific requirements. Here are some of our recent lifts:

Automated Test Equipment

Alum-a-Lift offer built-to-order solutions solutions for Automated Test Equipment (ATE) and In-Circuit Test (ICT). Our ATE lifts can load fixtures weighing up to 1,000 lbs. onto testers positioned in both flat and angled configurations. Models are also offered with 360° rotation, allowing safe access to the underside of test fixtures for service. ATE lifts with rotation can be used as mobile workstations and work positioners.

For fixture storage, we offer Alum-a-Racks that are fully compatible with our lightest, most maneuverable lifts.

The Standard Overload Safety Device (SOSD) is offered on all ATE lifts; this device can detect when the lift is overloaded or encounters a stationary obstacle, and it will halt lift travel to protect itself and your equipment.

Expert Service

Over 12,000 of our lifting devices are in use in more than 50 countries worldwide.

To ensure all of our clients have access to the support they need, Alum-a-Lift maintains a global network of factory-trained representatives. These agents are available for on-site discussion, troubleshooting, and support.

“Unique caster location & design meant the new Alum-a-Lifts could be maneuvered easily under full load by both female and male operators. This . . . is a testimony to what can happen when a world-class lifting solutions supplier like Alum-a-Lift understands customer needs & is prepared to invest time & energy in meeting those needs. Our confidence in Alum-a-Lift has driven us to place our next server [handling] lift order for multiple lifting solution again with Alum-A -Lift because this is a partnership that continues to work for us all.”

Engineer, Process Engineering, Server Manufacturing Company