Engineered Material Handling Solutions

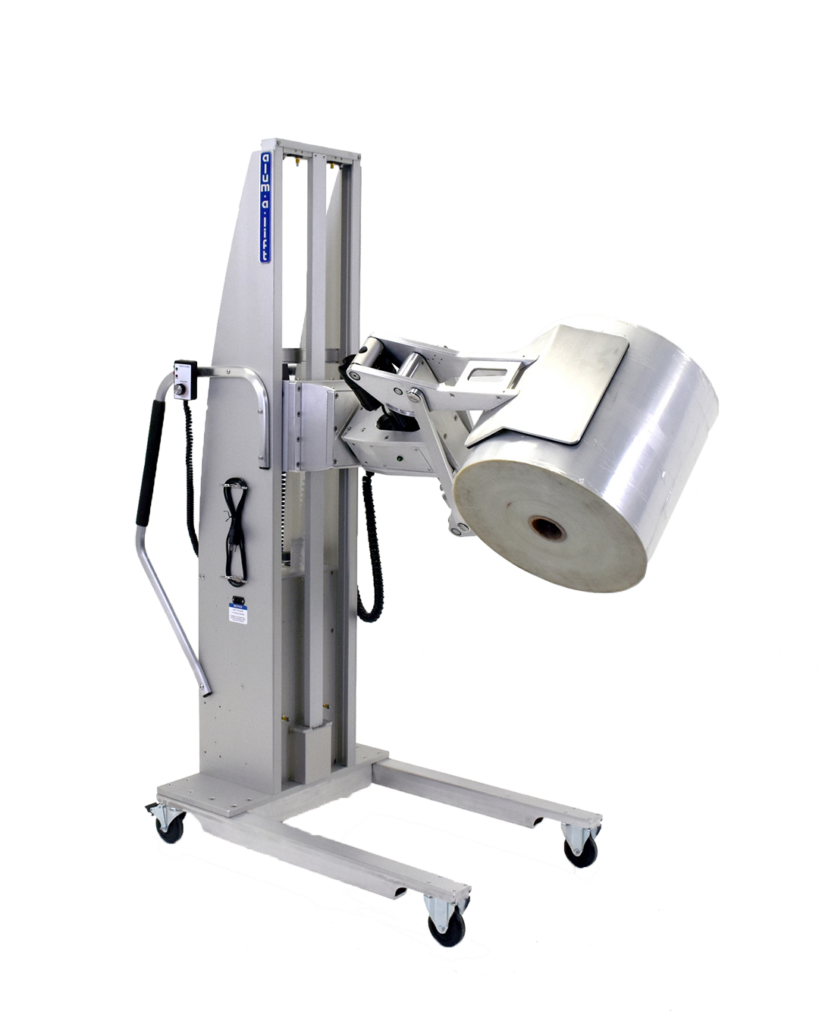

Alum-a-Lift offers an incredibly wide range of roll handling lifts, roll inverters, roll manipulators, and roll handling carts and racks.

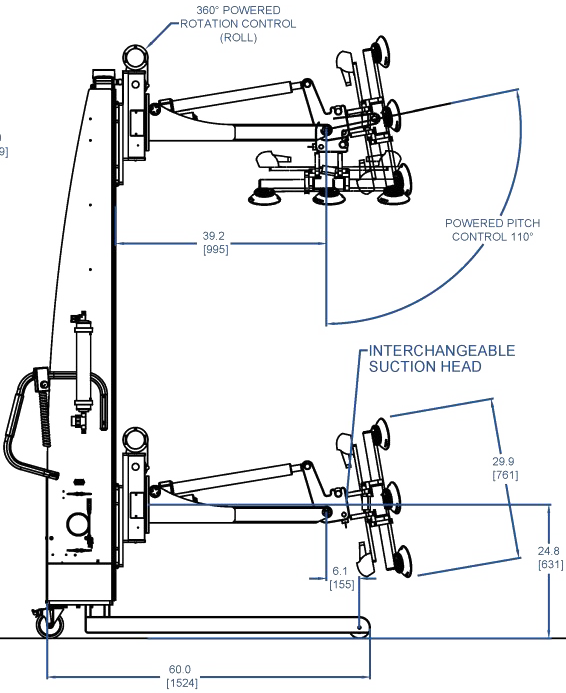

Our standard chassis offers proven lifting power and allows for heavier and dynamic side loads. Custom end-effectors provide precise manipulation designed specifically for the object you need to handle. Our compacts roll lifts can raise, move, and rotate rolls, core shafts, core plugs, dies, cutting heads, slitters, and more.

Every handling system undergoes rigorous factory testing and extensive QC inspections, ensuring your lift stand up to the demands of your process.

Built-to-order Lifts for Seamless Integration

Our lightweight, mobile roll lifters can handle rolls in a wide variety of configurations. As with all Alum-a-Lifts, our offerings are not “one size fits all.” Your lift will be a tailored fit, perfectly matched to your rolls’ size and weight, your process equipment, and the environment in which it will be used.

Our lifts can:

Other options include powered modules for very heavy loads, expanding mandrels that are interchangeable, quick-change batteries, and counterbalanced lifts.

Recent Roll Handling Lifts

Alum-a-Lifts are tailored to your specific requirements. Here are some of our recent lifts:

Expert Service

Over 12,000 of our lifting devices are in use in more than 50 countries worldwide.

To ensure all of our clients have access to the support they need, Alum-a-Lift maintains a global network of factory-trained representatives. These agents are available for on-site discussion, troubleshooting, and support.

“I did meet with the operators on the other line where we provided the larger lift . . . and they about kissed me! . . . One operator told me this lift was the best thing that [our company] had ever bought them for productivity and safety!”

Process Engineer, Food Packaging Line