We Have Your Back

Ergonomic Lifting Solutions to Protect Your Operators

Ergonomic Design From Top to Bottom

Ergonomic considerations are made for every aspect of an Alum-a-Lift. Each one is designed according anthropometric guidelines, ensuring they can be safely operated by the 2nd-percentile shortest female and the 98th-percentile tallest male.

Powered Lifting

Repetitive cranking and pedal pump operations are seldom ergonomically correct, so we make lifting a powered function.

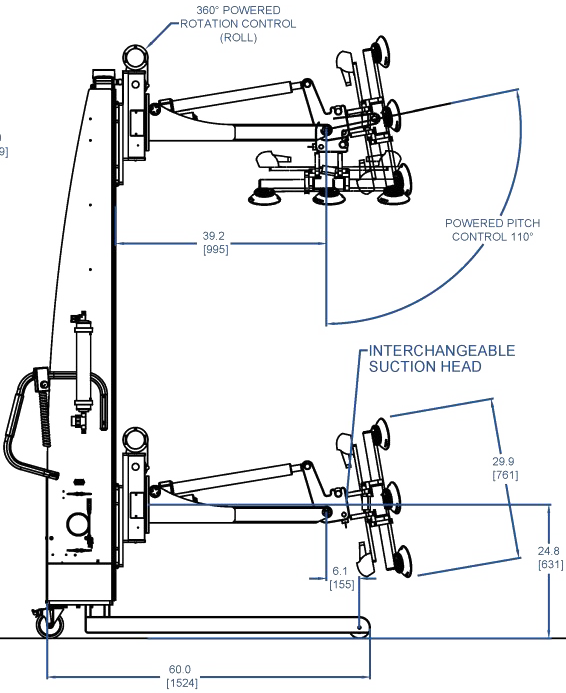

Powered End-Effector Motions

We offer end-effector motions in both manual and powered configurations. Manual operation is optimal for frequent, light motions, while powered motions can become necessary when the loads are heavy or out of reach. Alum-a-Lift’s engineers can help identify which is most suitable for a given task.

Intuitive, Hand-Held controls

Our team takes the elevations of controls and manipulations into consideration when configuring a system. A handheld pendant control is a standard feature, allowing an operator full visibility when positioning a load. Variable speed adjustment is a standard feature.

Push Force Considerations

Our engineers take push force into consideration for every lift. The amount of force necessary to move a lift, as well as travel frequency and distance, are considered, and we recommend high capacity casters or a steerable, powered drive wheel when appropriate.

Push Handles

Push handles are oriented at a natural angle and positioned at elevations reachable by the 2nd-percentile shortest female and the 98th percentile tallest male.

“Unique caster location & design meant the new Alum-a-Lifts could be maneuvered easily under full load by both female and male operators. This . . . is a testimony to what can happen when a world-class lifting solutions supplier like Alum-a-Lift understands customer needs & is prepared to invest time & energy in meeting those needs.”

Engineer, Process Engineering, Server Manufacturing Company

Tailored Options

In addition to these standard considerations, Alum-a-Lifts are built-to-order and customized to your processes. Because Alum-a-Lifts are not “one size fits all,” your operators won’t have to lug around a system that is too big and heavy for its task.