Proven Automotive Lifts

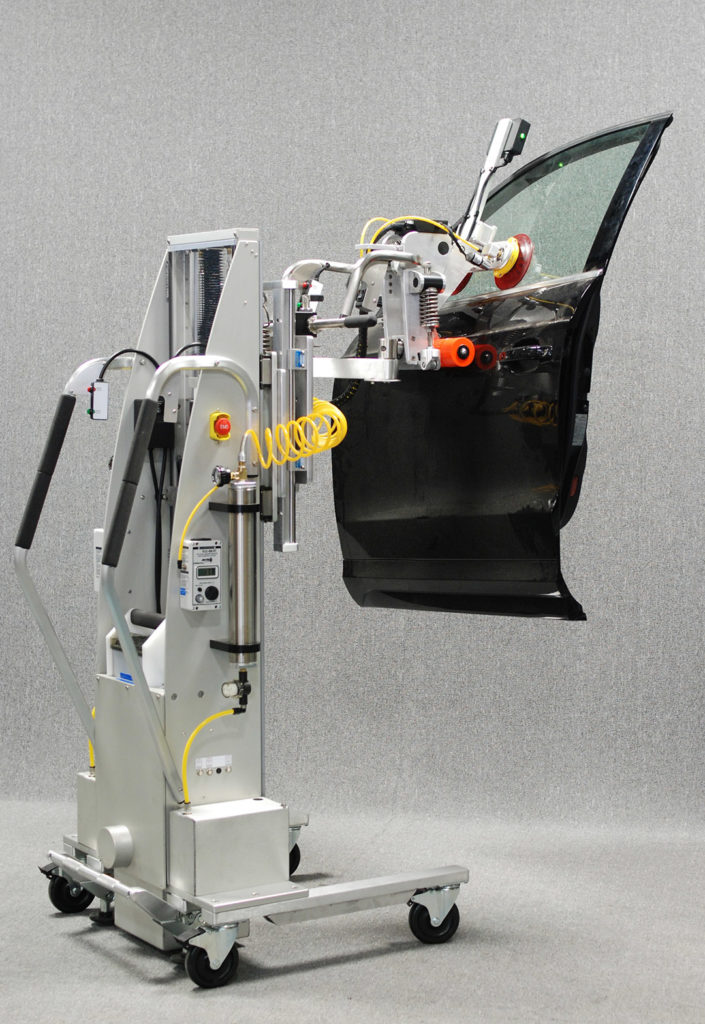

Alum-a-Lift is pleased to serve automakers and their suppliers, offering engineered material handling solutions for the entirety of their manufacturing processes. Our electric lifts use a combination of our proven dual-mast lift foundation and tailored components.

Alum-a-Lift designs address real-world off-center loading conditions, which are the largest contributor to failure in a lightweight lift system. Our dual-mast construction will withstand heavier side loads or dynamic side loads.

Every handling system undergoes rigorous factory testing that simulates actual use, and extensive QC inspections are performed prior to shipment.

Learn more about our automotive lifts throughout the automobile manufacturing process below:

Automobile Component Manufacturing

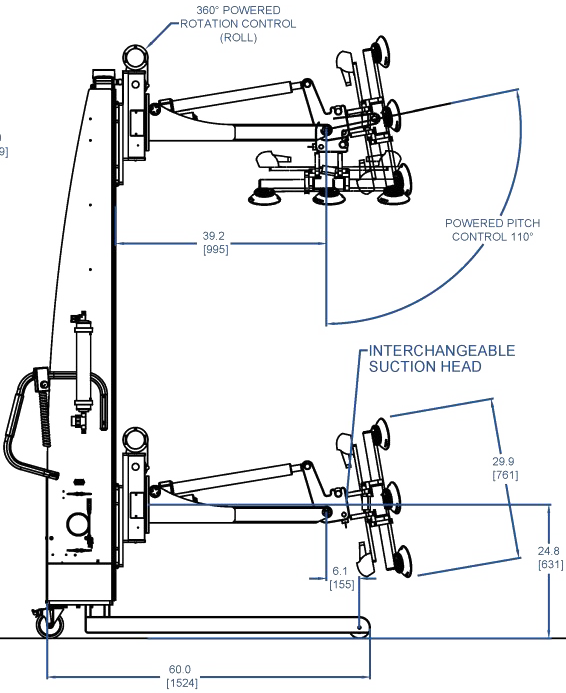

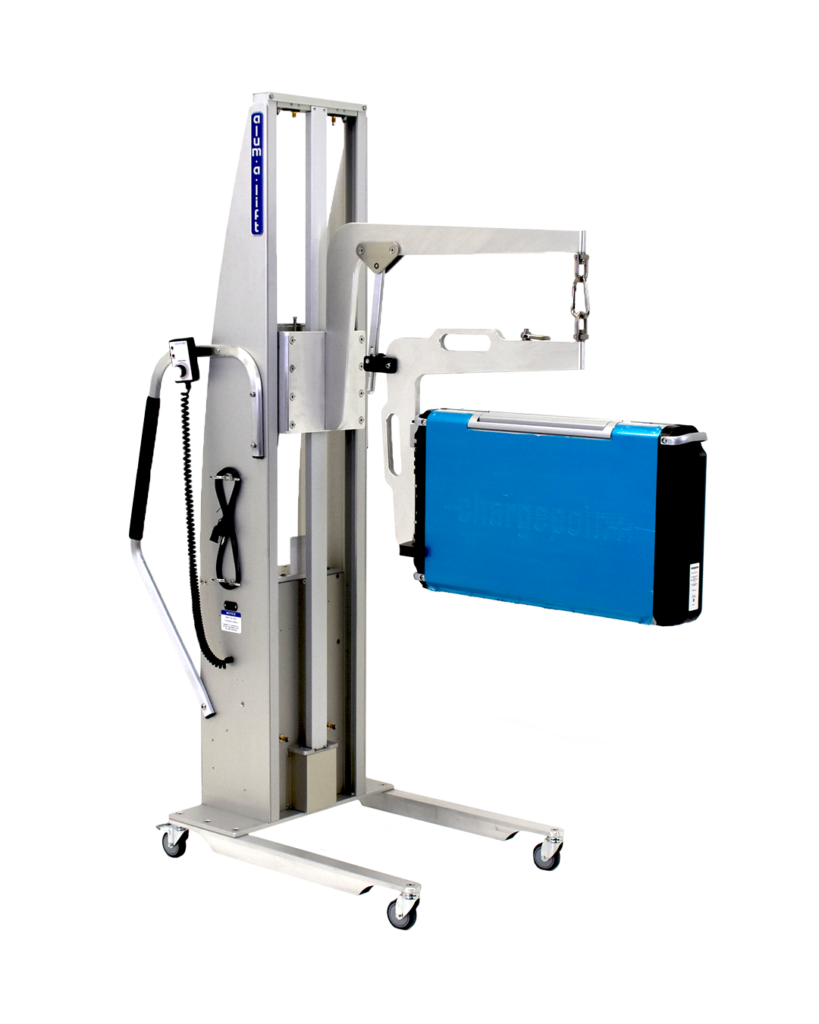

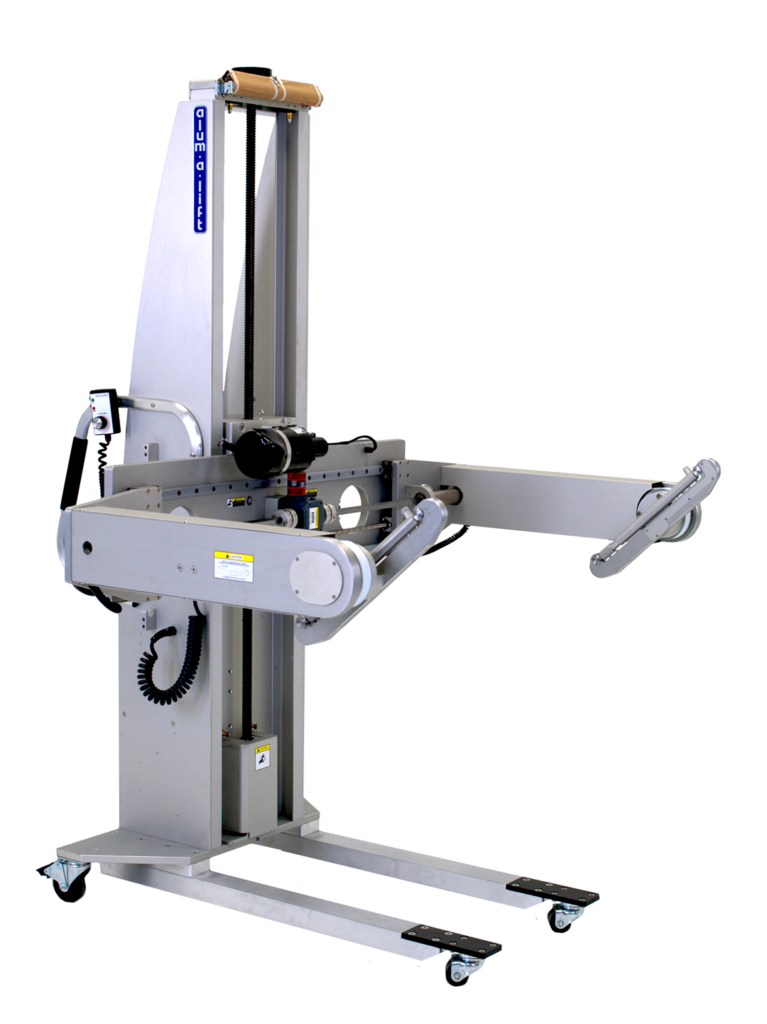

Alum-a-Lift’s lightweight battery powered lifts are useful in the manufacture and handling of tires, doors, windshields, seats, and modular subassemblies. Rotation and translation about all axes are available.

Lifts we have built include:

Automobile Electronics and Subassembly

All Alum-a-Lifts are optimized for your equipment, environment, and process. Our engineers minimize system weight and address narrow aisles, electrostatic discharge (ESD) concerns, overhead obstacles, grated flooring, and other challenges.

Alum-a-Lift can configure work positioners, allowing unencumbered access to all sides of a component. We can include adaptors to integrate a system with your existing fixturing, or provide a complete, turn-key handling system for the entire manufacturing cycle. Often, a single handling device can replace multiple overhead hoists or stationary balancers.

Automobile Final Assembly

While automation has proven value in automotive assembly, Alum-a-Lifts offer unique advantages on final assembly lines.

Alum-a-Lifts are portable, capable of moving with the line in case of mixed-mode or variable TAKT time operations. These lifts can work opportunistically without interfering with overhead hoists or other large equipment.

In smaller markets, Alum-a-Lifts can perform door, hood, hatch, or other large component assembly steps for local manufacturing where investment in robotics may be difficult to justify.

Alum-a-Lifts are perfect for occasional or low frequency tasks, providing additional coverage in pursuit of downtime reductions.

Alum-a-Lift’s mobile, modular approach eliminates the safety risks inherent with a below-the-hook system.

Recent Automotive Lifts

Browse our recent automotive lifts to get ideas for your next project:

"The lift itself is bulletproof. We use it daily and never had a down day in two years."

Tooling Engineer, Automotive Battery Manufacturer