Featured Alum-a-Lift

Semiconductor Lithography Inspection Lift

Project

32632

Featuring

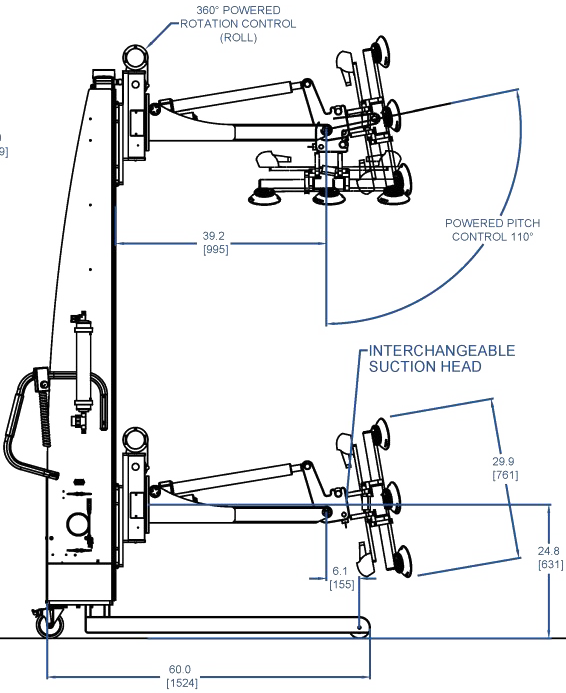

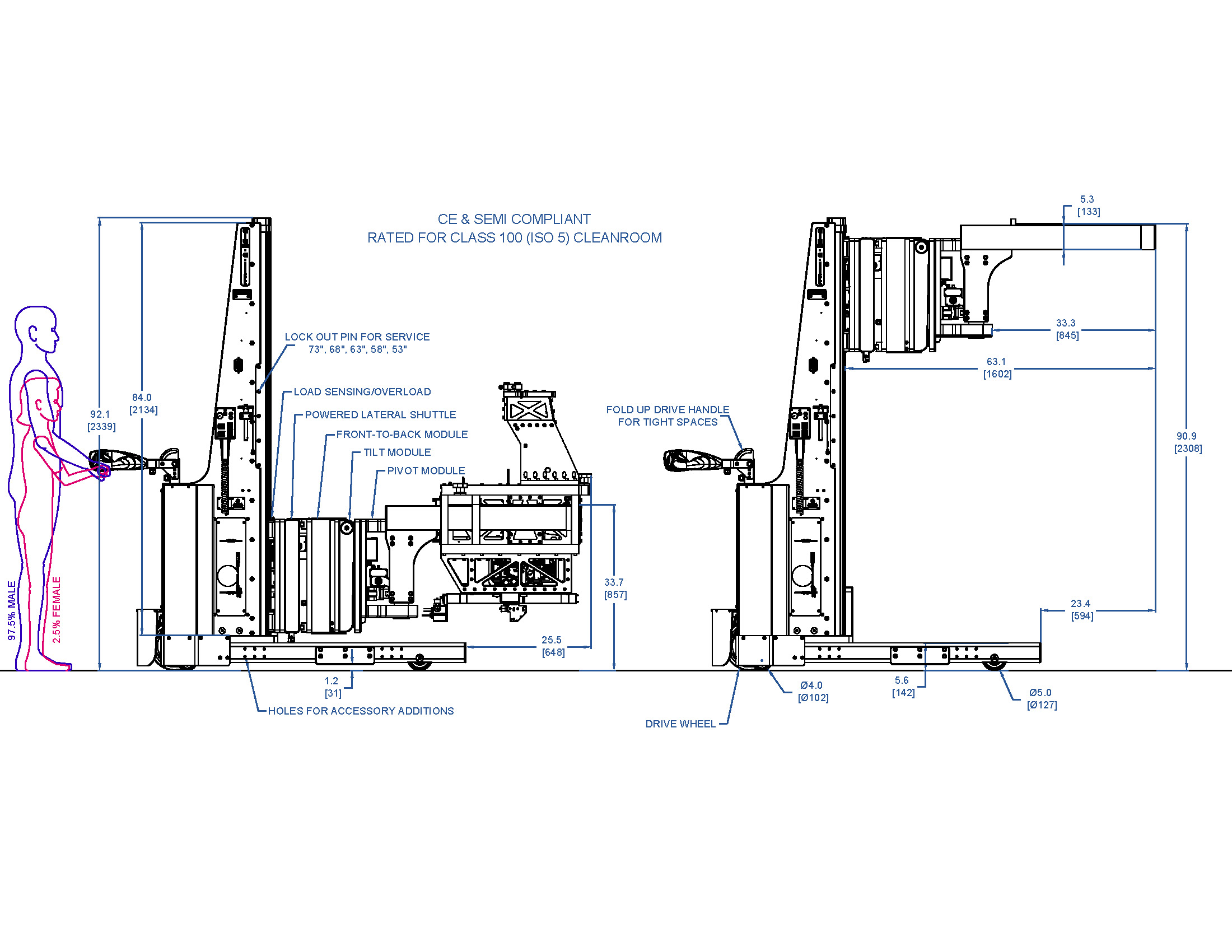

Lined Stainless Steel Fork Set, Powered Yaw and Pivot Rotation, Powered Front to Back Shuttle, Powered Lateral Shuttle, Laser Optical Alignment, Obstacle and Overload Sensing, Powered Drive Wheel, ISO 5 (Class 100 Cleanroom Rated, SEMI S2, CE Compliant

Handling

1660 lb [753 kg] Inspection Assemblies

Details

Designed for a global leader in nanometer-scale lithography defect inspection systems catering to semiconductor chip manufacturing, this lift system can perform detailed installation and maintenance operations with precise, repeatable placement of a heavy imaging component. The distinctive feature of this lift lies in its capacity to deliver powered movements with a remarkable resolution of under 100 microns, surpassing client expectations.