Featured Alum-a-Lift

High Capacity Ingot Gripper Lift

Project

30111

Featuring

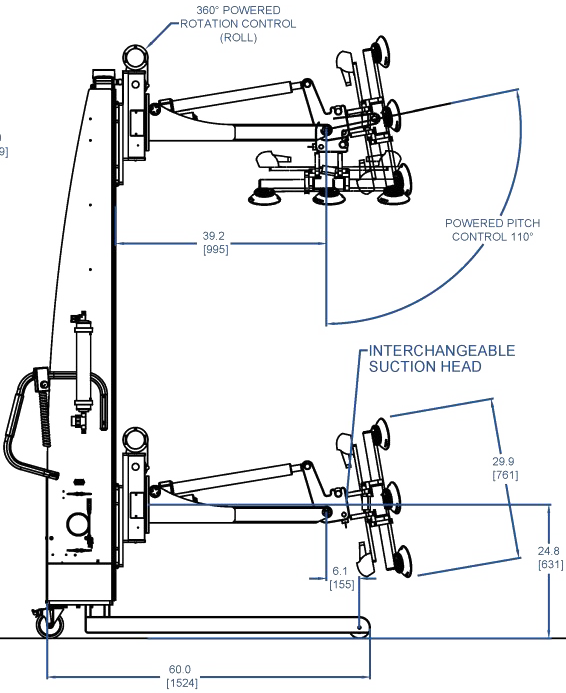

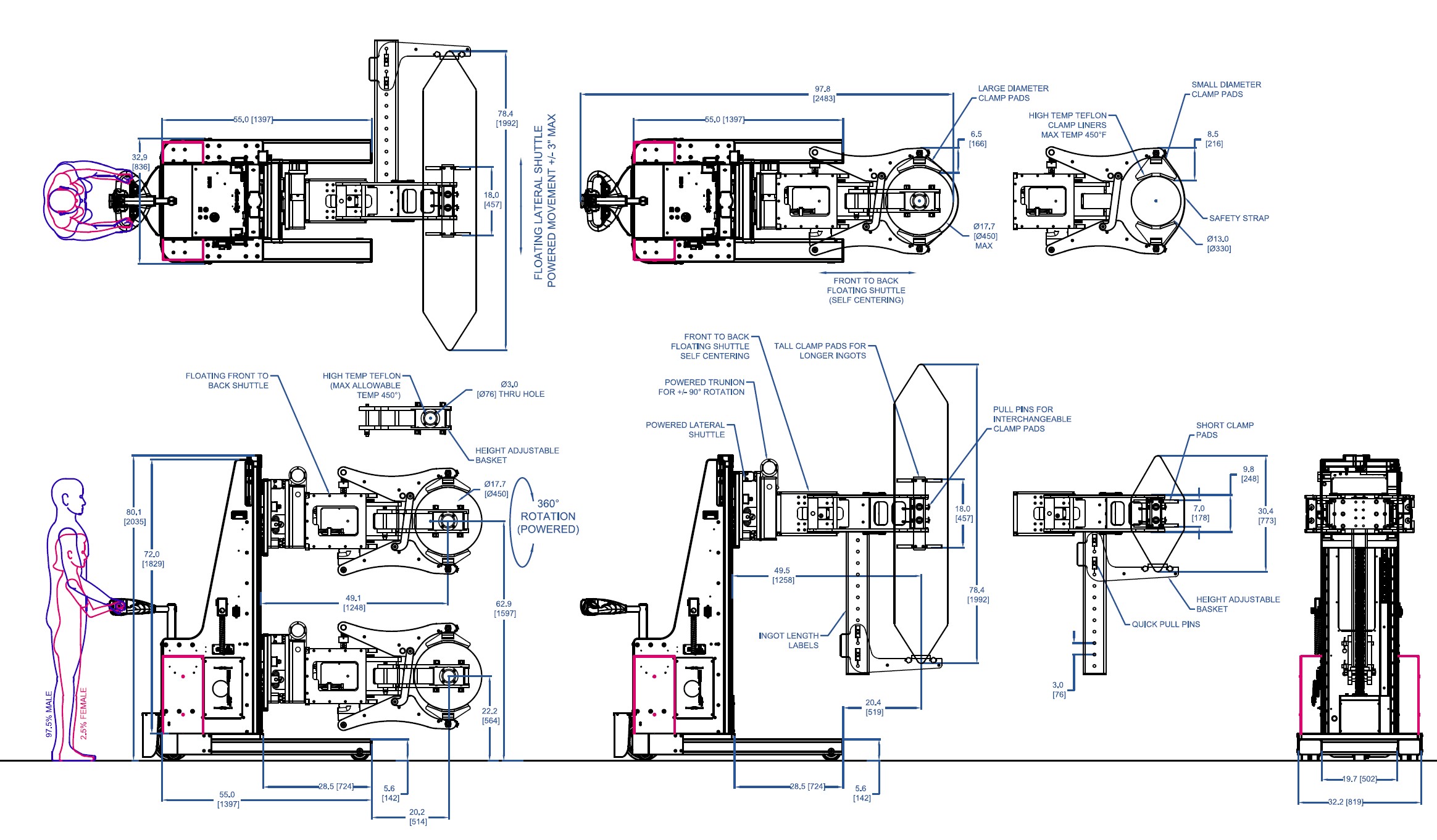

Power Drive, Floating Lateral Shuttle, Floating Forward Shuttle, Interchangeable Grips, Catch Basket

Handling

1100 lb [500 kg] Ingots

Details

Silicon wafer manufacturing starts with the production of pure silicon crystal ingots. The operators need a very precise way to handle hot ingots (up to 400° F) from the draw tower, and then rotate them onto an inspection cart. This lift features floating adjustment in the front to back and side to side directions for alignment purposes. The ingots can be several different diameters and lengths requiring interchangeable grip pads. An adjustable length catch basket supports the ingot from the bottom for security during gripping and rotation. This precise task required a meticulous tool.