Featured Alum-a-Lift

Self-Propelled Roll Lifter and Unwinder

Project

29559

Featuring

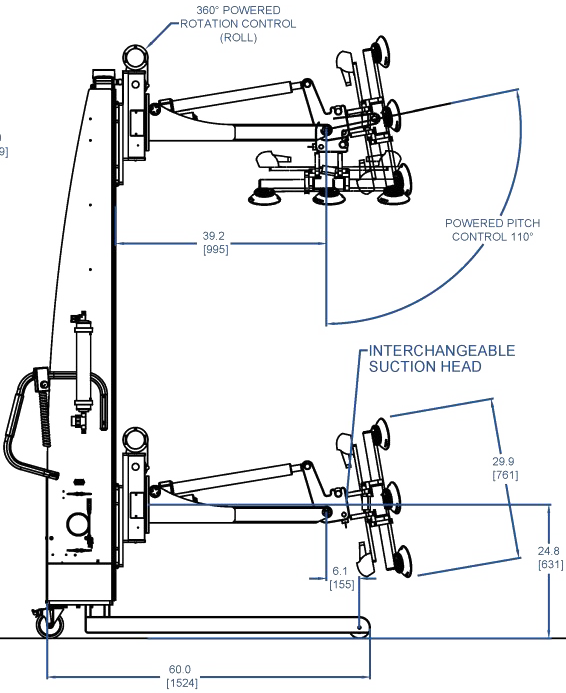

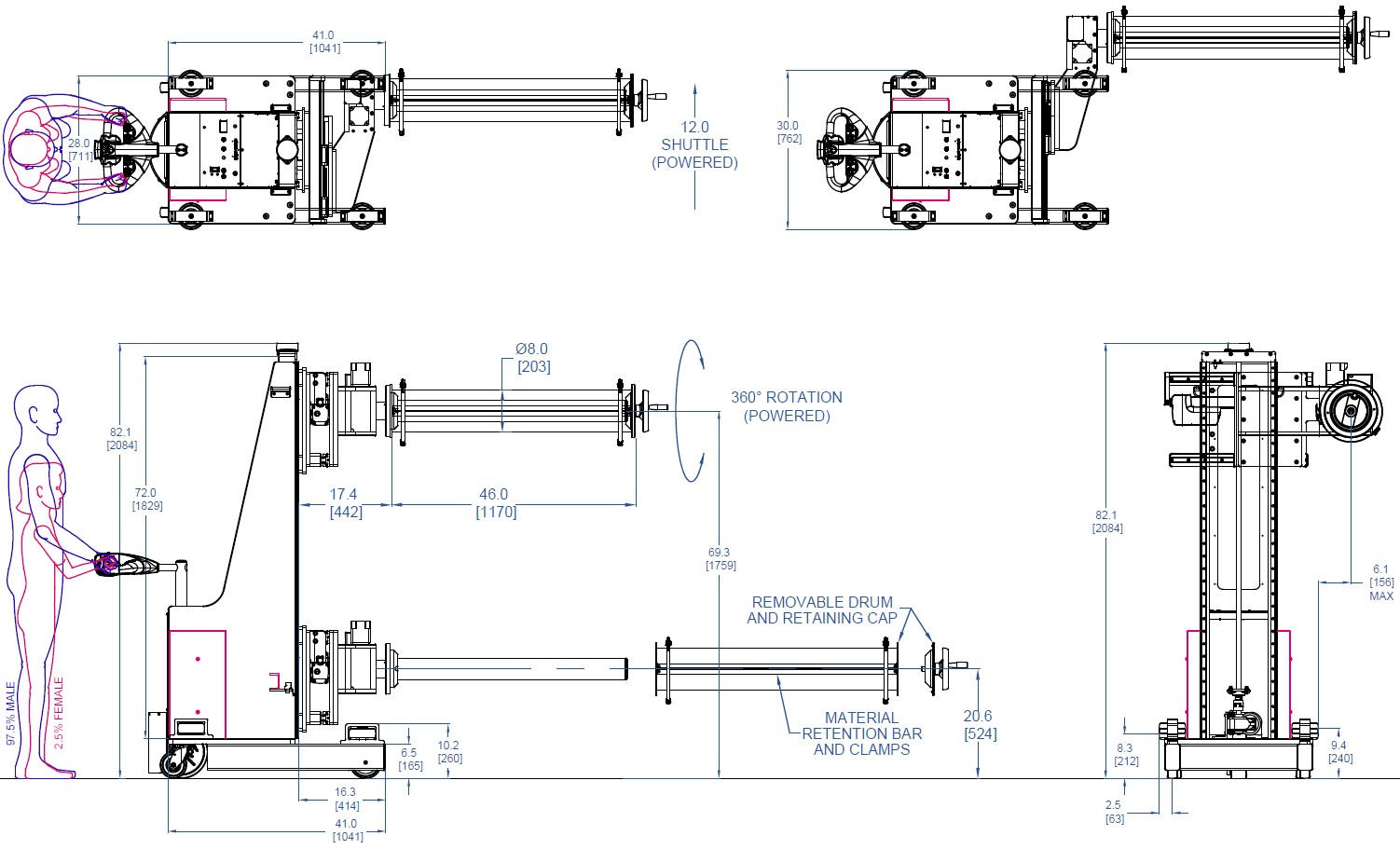

Removeable Drum Assembly, Powered Rotation, 12” Lateral Shuttle, Safety Bumper Wheels

Handling

200 lb [91 kg] Rubber Strips

Details

This Alum-a-Lift is designed to operate on a mezzanine above a bowl-shaped composite mold with a diameter of 28 ft. First, large triangular pieces of rubber are cut and rolled onto the lift’s removeable drum. The lift is then used to capture and raise the drum and can be driven to the correct position on the mezzanine with the lateral bumper wheels allowing the operator to drive right along the edge of the mold. A 12 in. shuttle positions the rubber over the edge of the mezzanine and the powered rotation module unrolls the material into the mold.