Featured Alum-a-Lift

Semiconductor Installation and Service Lift

Project

33230

Featuring

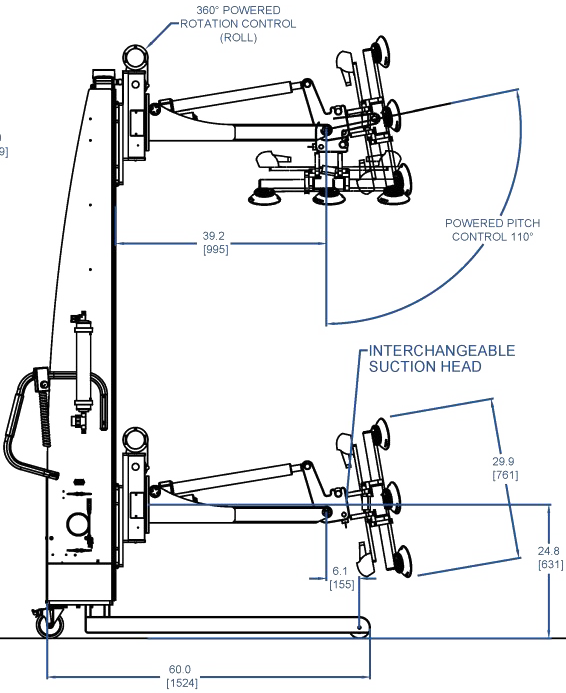

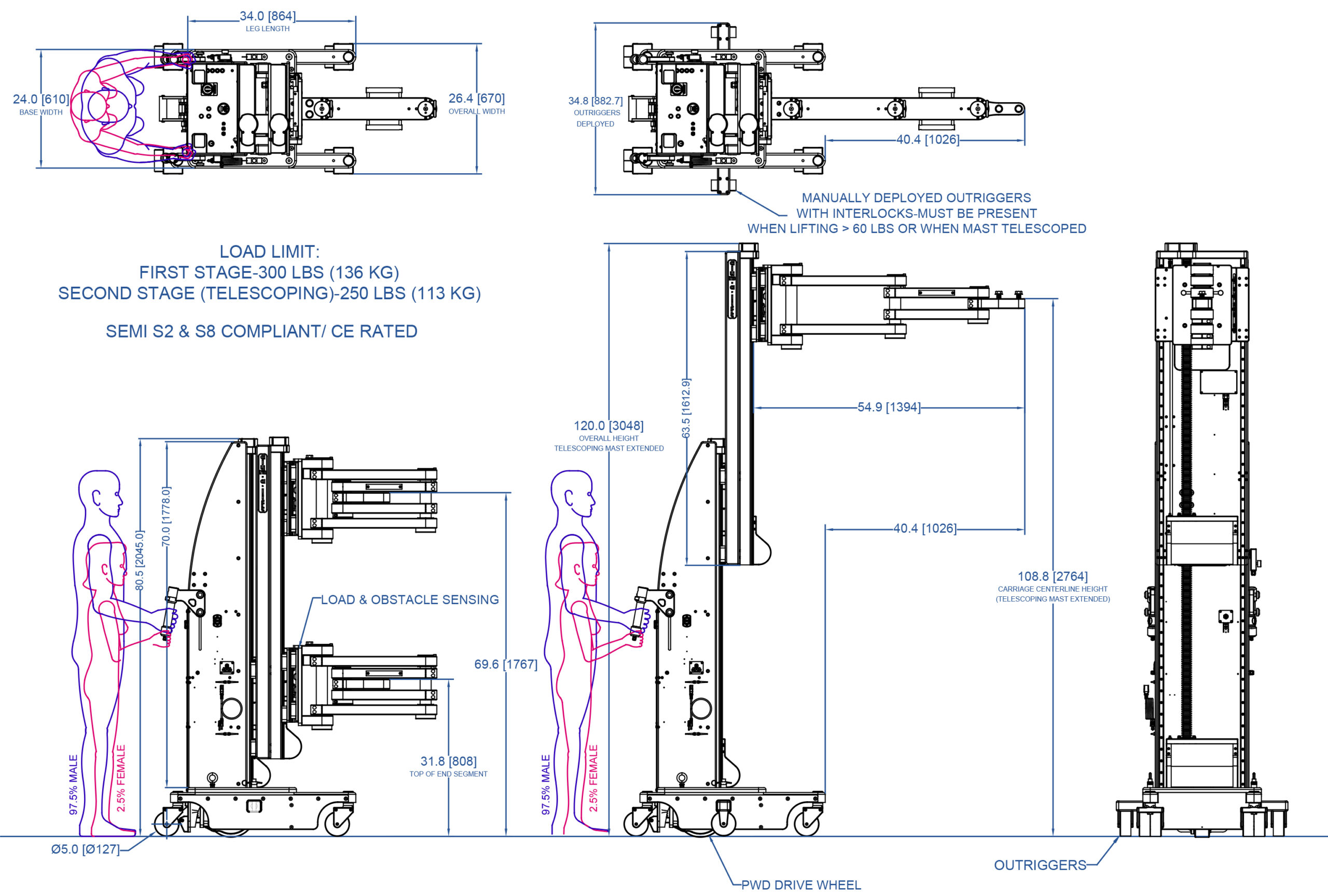

Articulated Arm w/ detachable component specific end-effectors, Obstacle and overload sensing, Powered Drive Wheel, Telescoping Mast, Deployable Outriggers, ISO 5 (Class 100) Cleanroom

Handling

250 lb [136kg]

Details

This lift was designed for a global leader in lithography inspection systems for semiconductor chip manufacturing. This Alum-a-Lift can assemble, install and service their tool which requires precise, repeatable movements within a small, confined area for both production environments and in the field. This tailor made, SEMI S2, CE Compliant solution adeptly handles a range of lifting needs, managing 28 different components while reducing downtime for maintenance and providing safe, ergonomic support to their customer.