Featured Alum-a-Lift

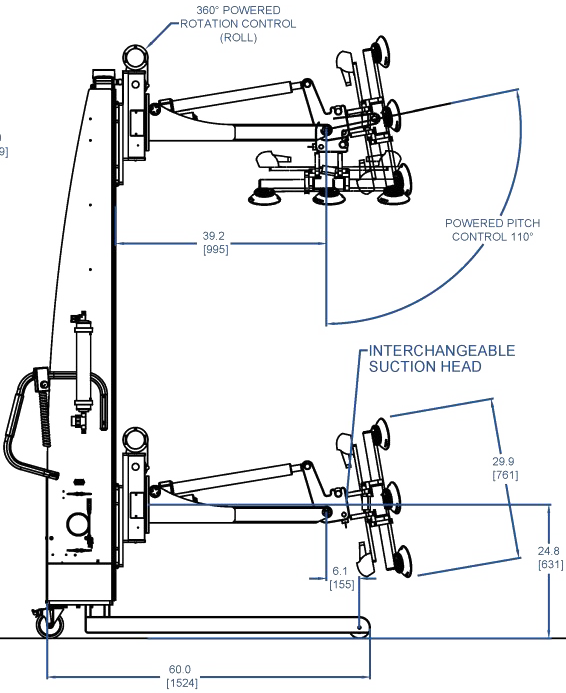

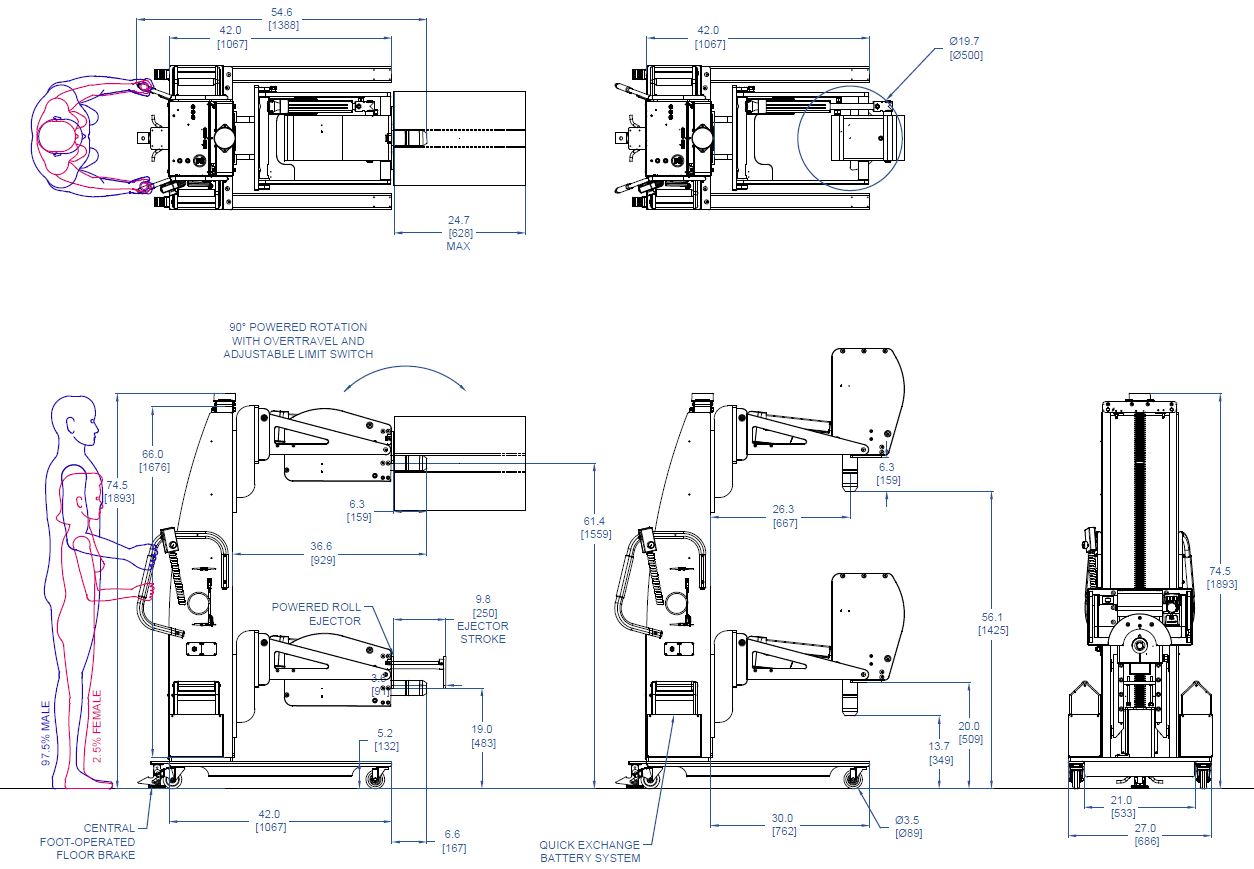

Roll Lift with Core Gripper and Powered Ejector

Project

32497

Featuring

Quick Exchange Batteries, Powered Core Gripper, Powered 90° Rotation, Powered Ejection

Handling

220 lb [100 kg] Rolls

Details

Packaging and bagging machines often utilized plastic materials on bulk rolls during the final phase of production. Depending on the speed of the machine and the size of the rolls, these will need to be replenished several times per shift. These are typically too heavy for an operator to safely lift and load. This lift can pick rolls from pallets by gripping the center core and rotate the rolls 90° to place onto a cantilevered shaft. Once the roll is piloted onto the shaft, an ejector pushes the roll the final distance. This allows a single operator to complete the full process without ever touching the rolls.