Featured Alum-a-Lift

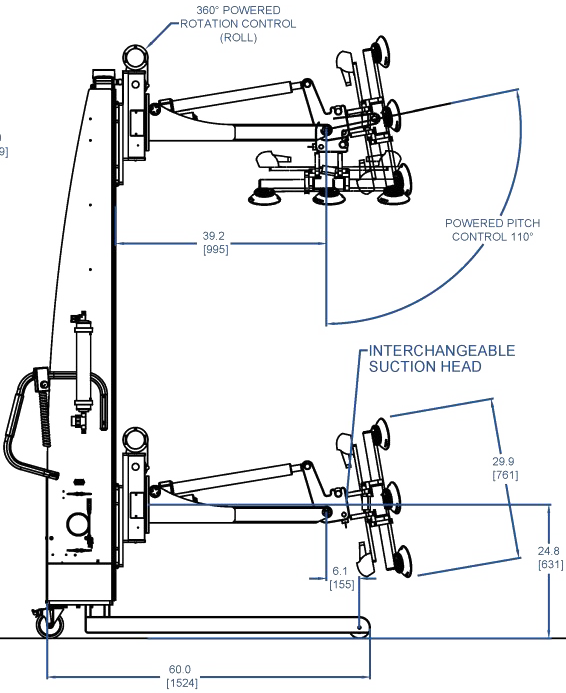

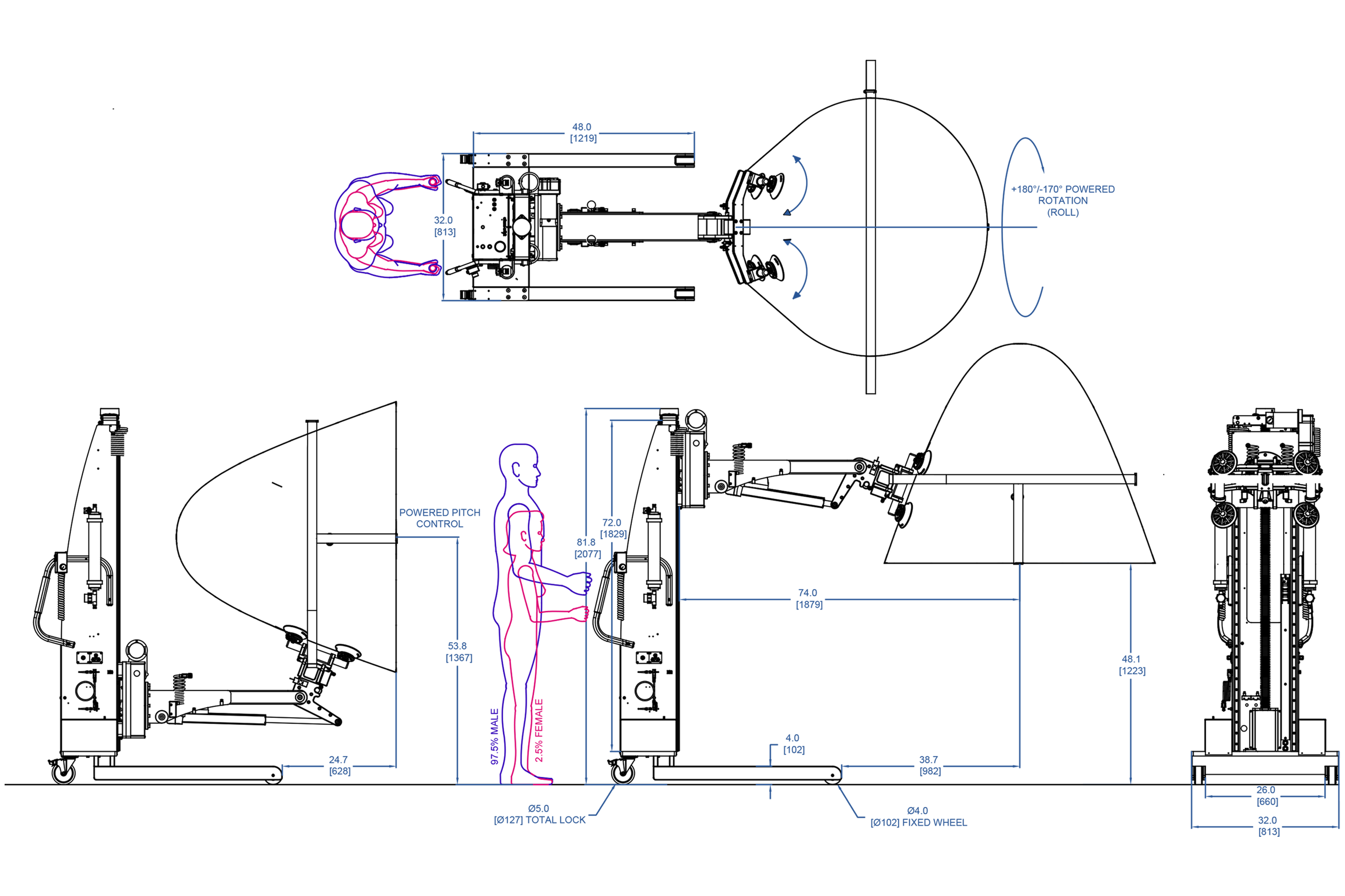

Aircraft Component Installation Vacuum Lift

Project

31321

Featuring

Powered Multi-axis Rotation, Dual On-board Vacuum System, Detachable Vacuum Head, Compliant Suction Cups, Redundant System with Vacuum Alarms for Safety

Handling

100 lb [45 kg] Nose Cones

Details

A global aircraft manufacturer needed to handle fiberglass nose cones throughout their process. The size and shape of the nose cone posed a challenge, and the customer needed to rotate the porous component into several orientations. A knuckling vacuum system with compliant suction cups proved to be the best solution that provided a safe and reliable system that one operator could use to handle a bulky component, thus reducing labor hours and potential damage to a critical component.