Featured Alum-a-Lift

Drum Dumper Lift for Cosmetics Manufacturing

Project

31193

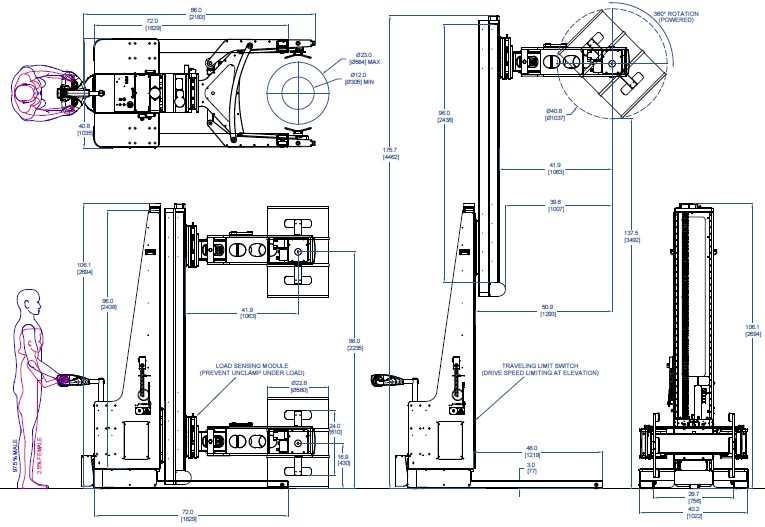

Featuring

Powered Clamp, Powered Front-to-Back Rotation, Overload/Load Sensing Module, Dual Lifting Stages, Low-Profile Legs, Steerable Powered Drive Wheel

Handling

600 lb [272 kg] Drums

Details

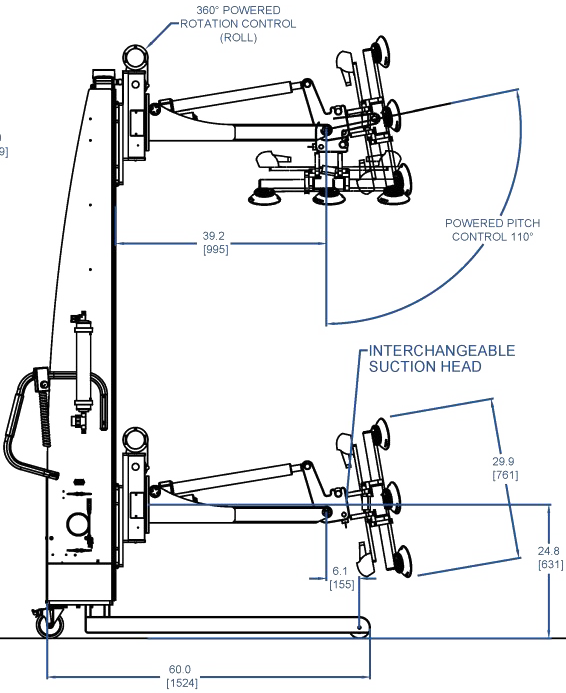

Large scale cosmetics manufacturing frequently requires dumping drums of ingredients into tall mixing kettles for blending. This mobile lift allows for the customer to load multiple blending kettles without having to source multiple dedicated lifts. The extended reach of the clamp and the low-profile legs enables the lift to reach over a mezzanine to pour the drums while the legs pass underneath the machine. Operators are able to control all powered functions from up on the mezzanine through a single tethered control pendant.