Featured Alum-a-Lift

Cassette Gripper for Additive Manufacturing

Project

29650

Featuring

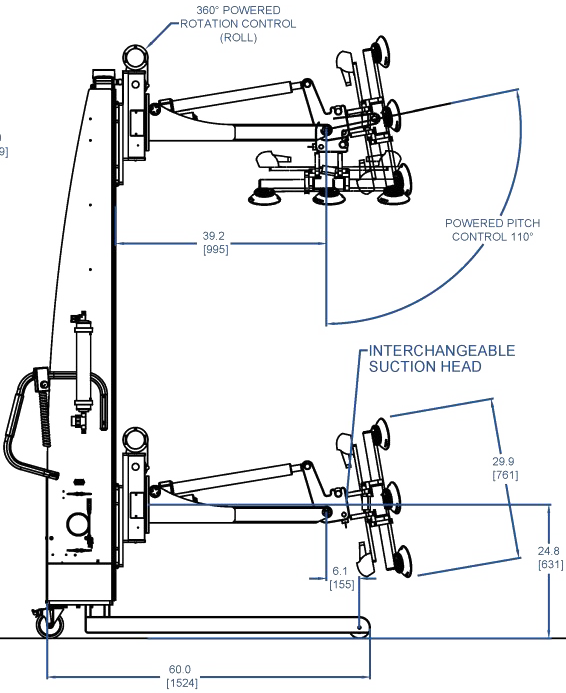

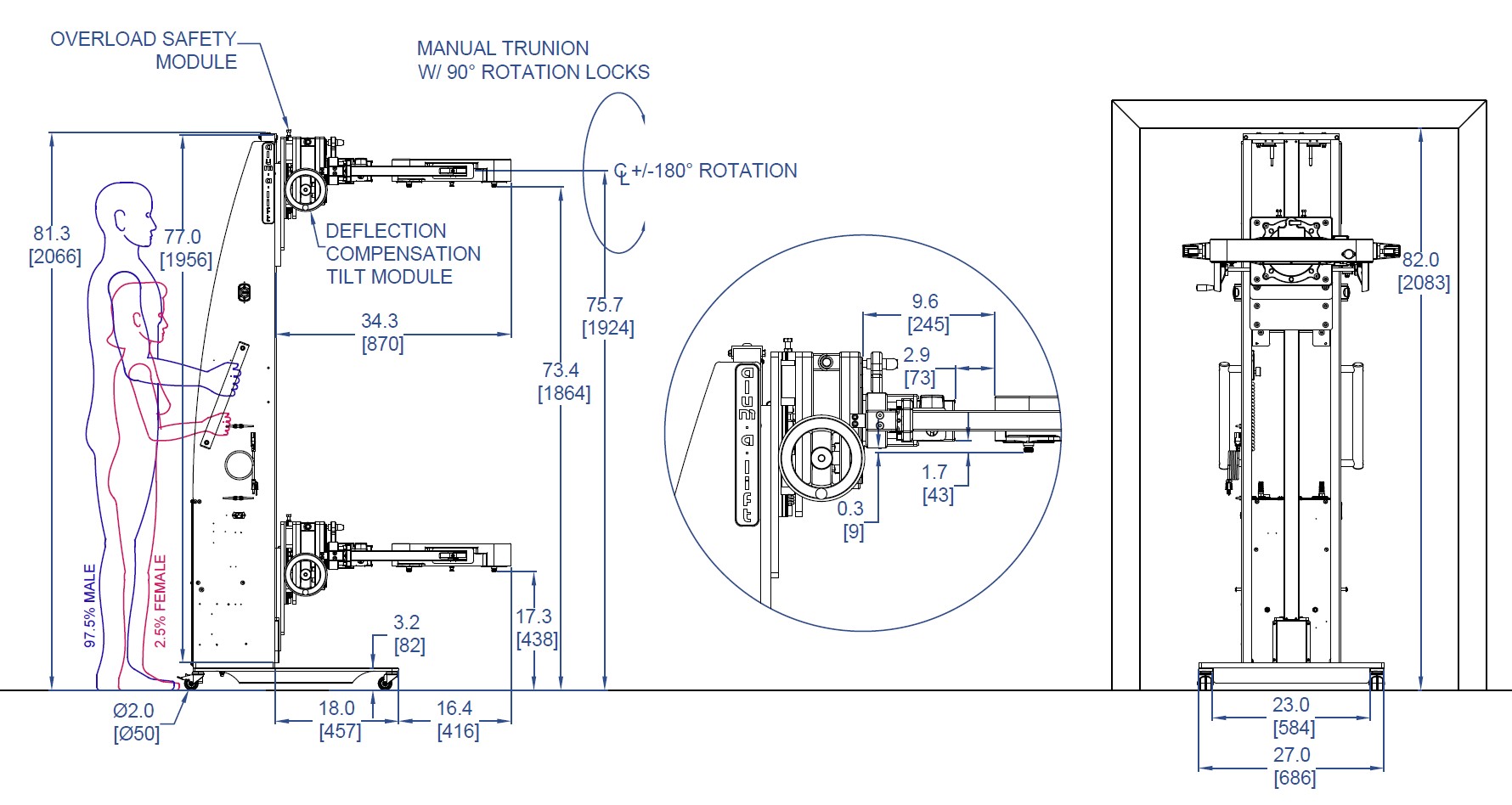

Powered linear clamp, embedded rotation module, deflection compensation module, spring overload safety device, low profile side push handles

Handling

70 lb [32 kg] Cassettes

Details

In an additive manufacturing process, a part is formed by using UV light to cure resin contained in a cassette. This lift is intended to manipulate these cassettes during the assembly and quality check steps of their manufacture. A rotating gripper was designed to securely hold the cassette and easily invert it. A deflection compensation “tilt” module allows precise positioning of the cassette on a granite work table, and a spring overload safety module prevents damage to the cassette from lift overtravel.