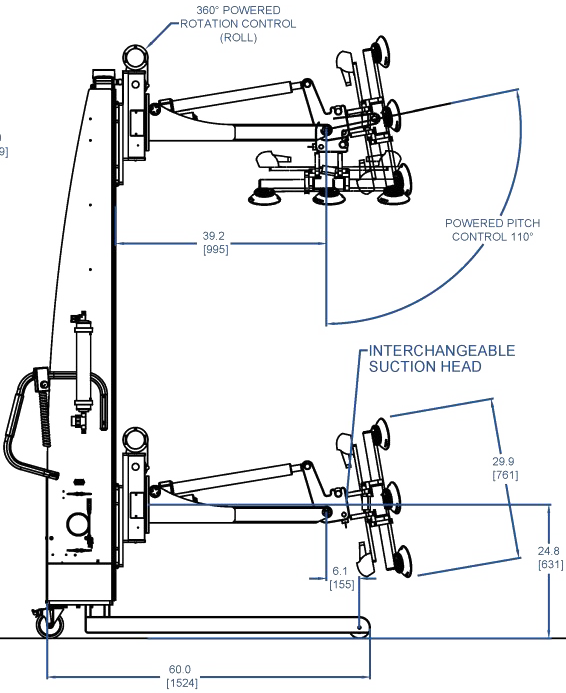

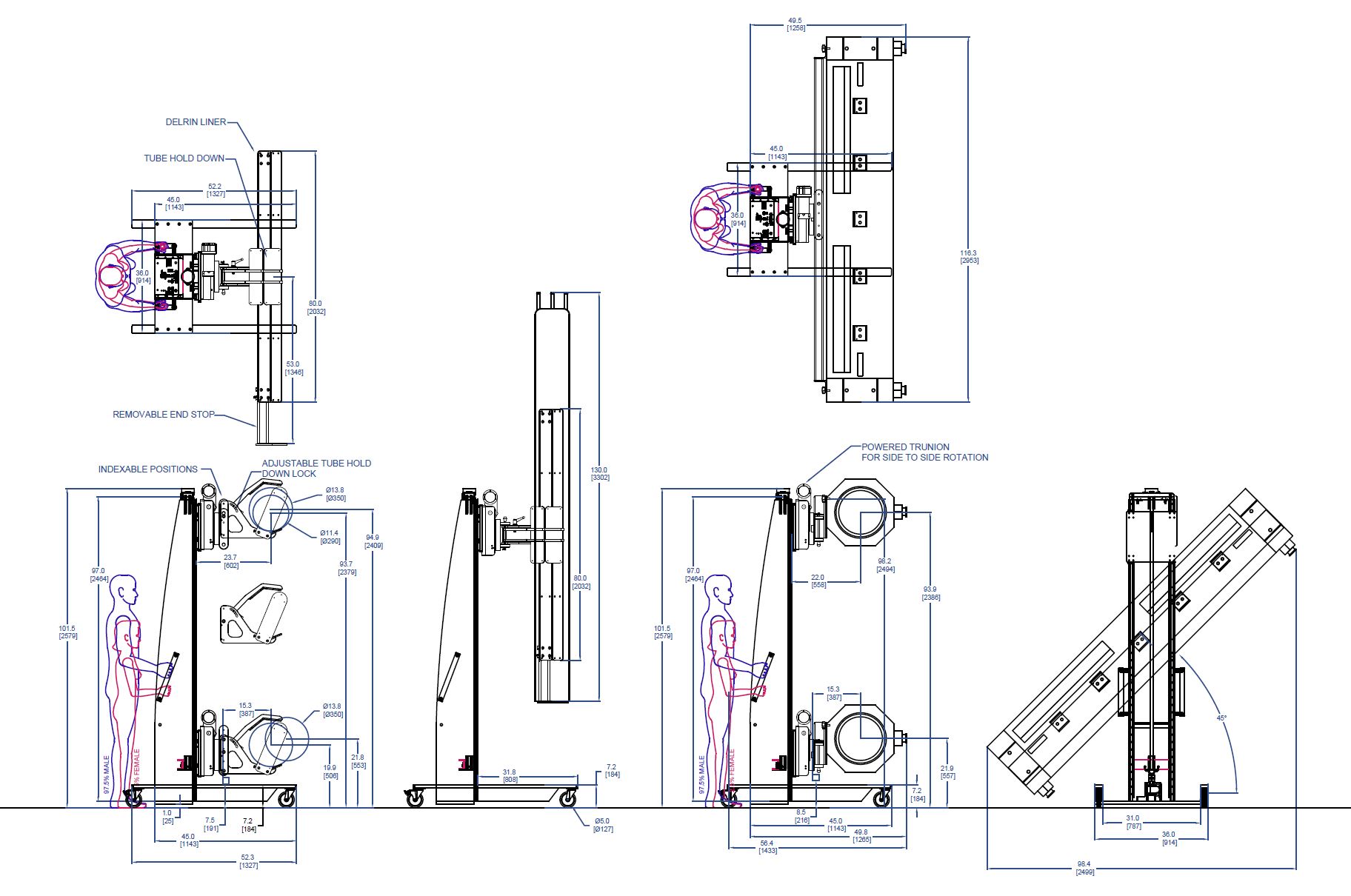

Featured Alum-a-Lift

Quartz Glass Rotator for Diffusion Furnaces

Project

27342

Featuring

Undermount legs, powered trunion, interchangeable endeffector adaptor, v-trough with hold down support and end stop, and lifting fixture

Handling

200 lb [90 kg] tubes and liners and 425 lb [192 kg] heating elements

Details

This lift was configured to support a large diffusion furnace used in the semiconductor and solar power industries. Pictured here, a rubber-lined v-trough end-effector was equipped with a hold down support arm, and adjustable end stop for quartz glass tubes and liners. A secondary fixture gave the lift the added ability to handle the furnace’s heating element assembly. This lift includes a powered rotation module, positioning components in a vertical orientation, and allowing the loaded system to travel through narrow aisles and doorways.