We Lift You Up

Built-to-Order Lifting Solutions For Every Manufacturing Need

Alum-a-Lift designs and manufactures turnkey ergonomic lifting solutions for companies around the world. From single custom units to multiple devices to entire lifting systems, our proven solutions help manufacturers meet their material handling needs safely and efficiently.

Our Lift Manufacturing Campus

Alum-a-Lift’s design and manufacturing operations are housed in our state-of-the-art facility located in Winston, Georgia. At over 50,000 square feet, our facility allows for a wide variety of manufacturing capabilities, so we can create a lift that meets your exact requirements.

Alum-a-Lift’s manufacturing capabilities include manual and CNC milling and turning, waterjet cutting, certified welding, sheet metal rolling and bending, inspection, assembly, wiring, and testing. Traceability is maintained using our ERP system, providing real-time process tracking on a per-piece and per-work cell basis.

Current and future clients are always welcome to tour the factory and demo material handling lifts that are currently in production. Because every project is unique, interesting opportunities for hands-on trials of ergonomic lifting equipment are always available.

Our World-Wide Presence

Over 12,000 of our ergonomic lifting devices are in use in more than 50 countries worldwide.

To ensure all of our clients have access to the support they need, Alum-a-Lift maintains a global network of factory-trained representatives. These agents are available for on-site discussion, troubleshooting, and support.

Our Local Engineering Team

Alum-a-Lift employs a world class team of mechanical engineers, who are involved in every step of a project’s life cycle. These project engineers work with our customers to develop the initial system specification, utilize CAD for design and analysis, and conduct multiple levels of review prior to the production of each lift. Engineer interaction continues through assembly and test, and on into available on-site training and after-sale support.

“We’ve come to know Alum-a-Lift as the go-to company for high performance, quality equipment.”

Technology Leader, Leading Consumer Packaged Goods company

Our History

Alum-a-Lift was founded in 1989 in response to the need for lightweight, compact, ergonomic, portable lifting equipment. Filling in the gap between traditional forklifts and the heavy, clunky, “portable” tools of the time, early Alum-a-Lifts featured a simple metal platform and a load capacity of only 100 lbs.

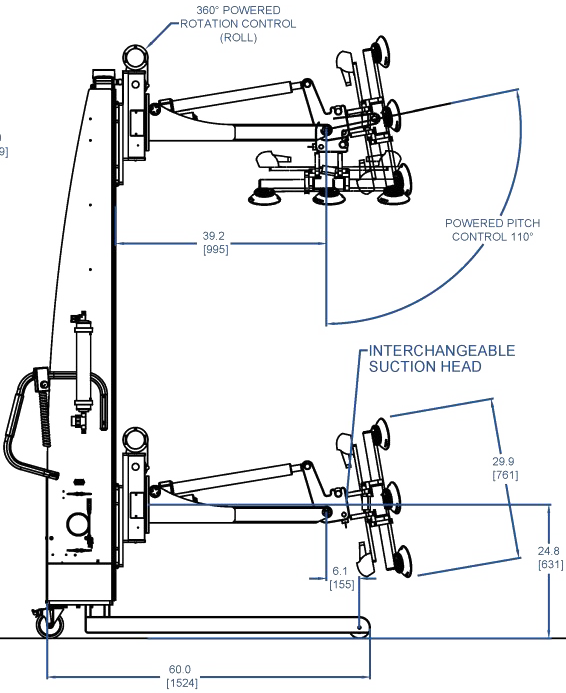

Alum-a-Lift exhibits a unique eagerness to listen and respond to our customers’ needs. Cleanroom compatibility, stainless steel constructions, load capacities exceeding several thousand pounds, self-propelled systems, intrinsically safe constructions, and the industry’s widest variety of custom end-effectors are all byproducts of saying “yes!”

Alum-a-Lift’s years of experience provide a comprehensive background in material handling, manufacturing, and custom lift design.