We Do the Heavy Lifting

Best-in-Class Lifting Equipment, Engineered for Your Process

We Do the Heavy Lifting

Best-in-Class Lifting Equipment, Engineered for Your Process

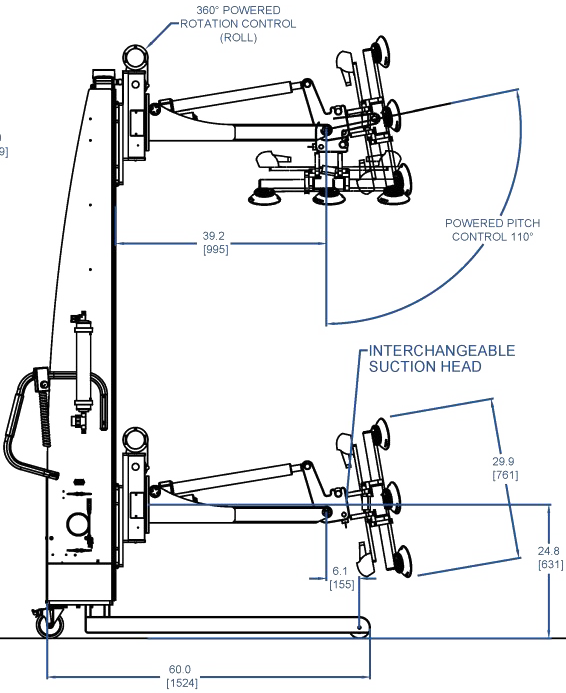

Built-to-Order Ergonomic Lifts

Used by nearly every Fortune 500 manufacturing company

Alum-a-Lift engineers and manufactures highly mobile lifts that are designed and built to your exact specifications. Our lifting systems can solve any heavy handling need, from the simplest to the most complex.

Proven Safety Features

Prevent drops, spills, and injuries with our engineered ball screw drive that addresses all known failure modes.

Industry-Leading Reliability

Minimize downtime with less than 2 hours of maintenance per year, optional quick-exchange batteries, and fast repairs.

Inherently Clean Designs

Keep your workplace clean with our corrosion-resistant chassis and all-electric drive train.

Buy-it-Once Durability

Experience superior value with high quality construction that outlasts its intended use, produced to your exact specifications.

We Raise the Bar on Ergonomic Lifting Equipment

Alum-a-Lift is your partner in creating a complete process solution, not just a piece of equipment.

Our highly skilled Engineers listen to your needs and get the exact specifications for your project. Then we work with you to design the perfect piece of equipment using a combination of our proven components and customized end-effectors.

With a foundation of industry-tested solutions, we’ve already engineered most of your project. And the customized pieces are what will make you and your operators love our lifts.

Watch our video to learn more about how it works.

Industries

Found in over 50 countries and in dozens of industries, Alum-a-Lifts are the flexible solution to your manufacturing needs.

Image Gallery

Get inspiration for your project.

“I did meet with the operators on the other line where we provided the larger lift . . . and they about kissed me! . . . One operator told me this lift was the best thing that [our company] had ever bought them for productivity and safety!”

Process Engineer, Food Manufacturing Company